Thermovision can be used in all areas of activity, but it brings the greatest advantages when used in the field of electrical installations. It is a popular choice in industrial and commercial fields due to its various benefits as it is the best tool for performing investigations and diagnostics.

Electrical systems, although durable, should always be regularly inspected and maintained to prevent any faults from occurring over time, from increased contact resistance, loose connections, to imbalances or overloads. Electrical devices and networks are prone to failure due to high temperature and resistance. These two factors can cause significant damage and disruption if not properly addressed.

How does thermal imaging help us identify faults in electrical installations?

Each element of any electrical installation has a specific resistance and in turn consumes energy. Thus, the total power consumed depends on the resistance of the components. Improperly assembled machines and appliances may experience increased resistance due to construction or installation faults.

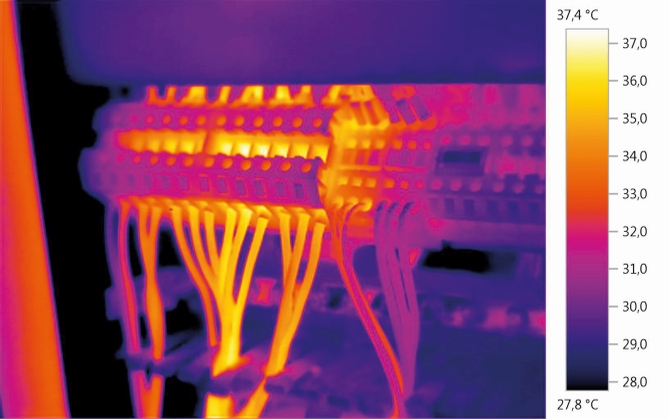

An increase in the resistance of a component leads to a higher power consumption, thus it will result in more heat being released during the process. Thermographic inspection is a tool that helps to identify elevated thermal points that may be caused by faulty equipment, loose connections or high contact resistances.

Thermal imaging cameras are able to detect temperature rises in electrical components before they fail, which is a very useful tool. It provides early detection so companies can take the necessary steps to prevent potential problems.

By detecting temperature rises early, the chances of a fire breaking out are greatly reduced. This can help avoid power outages and reduce maintenance costs.

Which installations can be checked by Thermography?

– Lighting panels and sockets;

– general electrical panels;

– electrical substations, transformer stations;

– main circuit breakers, load breakers

– UPS

– control panels for various machines, motors, etc.

– AAR

– stationary batteries

– capacitor banks

What can we detect with Thermovision?

– imbalances in the three-phase electrical network

– overload of circuits or equipment

– faulty protective devices

– loose or damaged connections

– inductive heating

– presence of harmonics

What are the signs that we should carry out a thermal imaging inspection?

If you suspect something is wrong with your electrical installation, but cannot determine this by other methods of investigation, it is recommended that you have a thermographic scan of an electrical installation regularly to ensure that it is in optimal working order. For normal working regimes, an annual scan should be sufficient, while for installations subject to vibration, it is advisable to scan every six months.

To keep your electrical system safe and operational, our thermal imaging service is the ideal choice. In addition, it can help extend the life of your equipment.

ELECTRO INSTAL CONSTANTIN offers professional electrical installation testing services ensuring the safety and efficiency of your systems. Popular services include PRAM checks to assess your grounding installation and PAT testing for electrical equipment and for the Electrical Installation Thermal Imaging procedure.